MS DUCT FABRICATION SERVICE

MS DUCT FABRICATION SERVICE Specification

- Diameter

- Customized as per requirement

- Shape

- Rectangular/Circular

- Product Type

- 1. Construction & Infrastructure 2. Manufacturing & Engineering 3. Automobile & Transportation 4. Oil & Gas 5. Power & Energy 6. Waste-to-Energy & Solid Waste Management 7. Agriculture & Farming 8. Railways & Metro Projects 9. Aerospace & Aviation 10. Food Processing & Packaging 11. Shipbuilding & Marine 12. Defense & Security 13. Textile & Garment Industry 14. Pharmaceutical & Chemical Industry 15. Hospital & Medical Equipment

- General Use

- Industrial Air Ducting, HVAC, Exhaust, Ventilation Systems

- Material

- Mild Steel (MS)

- Type

- Rectangular, Circular, Spiral Ducts

- Capacity

- Custom as per requirement

- Weight (kg)

- Varies depending on size and thickness

- Computerized

- No

- Automatic

- No

- Touch Screen

- No

- Control System

- Manual Operation

- Surface Treatment

- Galvanized, Painted or Natural Finish

- QC System

- Visual and Dimensional Inspection

- Tolerance

- 2 mm

- Drawing

- As per Customer Specification

- Dimension (L*W*H)

- Custom as per drawing/specification

- Feature

- Corrosion Resistance, Durable, Custom Fabrication

- Color

- Silver or as required

- Welding Method

- Arc Welding, MIG Welding, Spot Welding

- Available Sizes

- Standard and Custom Sizes

- Installation Service

- Available

- Usage/Application

- Air Conditioning, Ventilation, Fume Extraction, Dust Collection

- Corrosion Protection

- With or without coating as per client need

- Lead Time

- 2-4 weeks depending on order size

- End Connection

- Flanged, Slip-on, Couplers etc.

- Sheet Standard

- IS 277/IS 2062 or as specified

- Thickness

- 0.6 mm to 3 mm (customizable)

MS DUCT FABRICATION SERVICE Trade Information

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 3000 Tons kg/ton Per Week

- Delivery Time

- 1000 Kg/day Days

About MS DUCT FABRICATION SERVICE

We specialize in high-quality MS (Mild Steel) fabrication, offering customized solutions for industrial, commercial, and residential applications. Our services include cutting, welding, bending, and assembling of mild steel components for structures, machinery, pipelines, frames, and customized designs. With a focus on precision, durability, and cost-effectiveness, we cater to diverse industries, ensuring robust and reliable fabrication work. Our expert team uses advanced techniques and modern equipment to deliver projects on time while maintaining high standards of craftsmanship. Contact us for custom MS fabrication solutions tailored to your requirements.Comprehensive Customization

Our MS duct fabrication service allows precise customization in thickness, size, and shape as per your projects specific needs. Whether you require rectangular, circular, or spiral ducts, we accommodate your specifications, ensuring seamless integration into your HVAC or industrial process systems.

Quality Assurance and Standards

We adhere strictly to established sheet standards such as IS 277 and IS 2062, guaranteeing robust and reliable fabrication. Every duct undergoes thorough visual and dimensional inspection to maintain high-quality standards and performance under demanding industrial conditions.

End-to-End Service

From fabrication to installation, our team offers complete support to deliver efficient, corrosion-resistant MS air ducting solutions. With flexible lead times of 24 weeks and installation available, we ensure your systems are operational on schedule, making us a dependable partner for industrial air management projects.

FAQs of MS DUCT FABRICATION SERVICE:

Q: How can MS duct fabrication be customized for my specific project requirements?

A: Our MS duct fabrication is tailored to your specifications, including thickness from 0.6 mm to 3 mm, shape (rectangular, circular, spiral), size, end connections, surface treatment, and features such as corrosion protection. Simply provide your drawings or specifications and our team will fabricate accordingly.Q: What welding methods are used in MS duct fabrication?

A: We employ Arc Welding, MIG Welding, and Spot Welding methods based on the application and project needs. This variety ensures strong, consistent joints and reliable duct performance for air conditioning, dust collection, and ventilation systems.Q: When is installation service available for MS ducts?

A: Installation service is available after duct fabrication is complete, typically within a lead time of 24 weeks depending on the order size. Our skilled team will ensure proper setup and integration within your industrial or commercial site.Q: Where are your MS duct fabrication and installation services offered?

A: We provide duct fabrication, supply, and installation services across India, serving distributors, fabricators, manufacturers, suppliers, traders, and wholesalers involved in industrial air ducting and HVAC projects.Q: What is the process for ordering custom MS ducts?

A: To order custom MS ducts, share your requirements and drawings with our team. We offer consultation, prepare a detailed quote, fabricate the ducts as per your specifications, and provide installation if required, ensuring a seamless end-to-end experience.Q: How is corrosion protection handled for MS ducts?

A: Corrosion protection is available either with galvanized coating, painted surfaces, or left natural, based on client preference. This flexibility ensures the ducts perform well in various environments and prolongs their operational lifespan.Q: What benefits do MS ducts fabricated under your service offer?

A: Our MS duct fabrication ensures corrosion resistance, durability, and precise customization to fit any industrial or HVAC application. Superior welding, inspection, and surface treatment deliver reliable air management solutions for challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spare Parts For Transit Mixer Category

MS BASE FRAME FABRICATION

Price 4000.0 INR / Ton

Minimum Order Quantity : 5 Pieces

Computerized : Yes

Control System : Other

Feature : Other, High Strength, Rugged Build, Corrosion Resistant, Precise Dimensions

Automatic : No

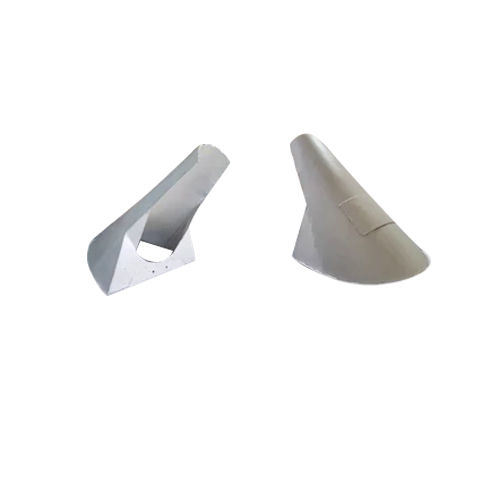

DKV Discharge Chute for the Transit Mixer Machine

Price 18000 INR / Piece

Minimum Order Quantity : 2 Pieces

Computerized : No

Control System : Manual

Feature : Easy to use

Automatic : Yes

DKV V Chute For Transit Mixer Machine

Price 5000 INR / Piece

Minimum Order Quantity : 10 Pieces

Computerized : No

Control System : Manual

Feature : Easy to use

Automatic : Yes

DKV Charging Chute for Transit Mixer Machine

Price 15000 INR / Piece

Minimum Order Quantity : 2 Pieces

Computerized : No

Control System : Manual

Feature : Easy To Move

Automatic : Yes