MS BASE FRAME FABRICATION

MS BASE FRAME FABRICATION Specification

- Shape

- Rectangular / Custom

- Product Type

- MS BASE FRAME FABRICATION

- General Use

- Industrial Machinery Support, Equipment Mounting

- Material

- Other

- Type

- Welded Fabricated Structure

- Capacity

- Custom as per requirement

- Weight (kg)

- 150 - 500 kg (Depending on size & design)

- Computerized

- Yes

- Automatic

- No

- Touch Screen

- No

- Control System

- Other

- Surface Treatment

- Other

- QC System

- Visual Inspection, Dimensional Check, Welding Quality Test

- Tolerance

- Up to 1 mm

- Drawing

- Other

- Dimension (L*W*H)

- Custom as per drawing (Typical: 2000 x 800 x 400 mm)

- Feature

- High Strength, Rugged Build, Corrosion Resistant, Precise Dimensions

- Color

- Black, Blue, Grey, or as specified

- Assembly

- Delivered Fully Assembled or Knocked Down as per request

- Grade of Steel

- IS 2062 / Equivalent

- Corrosion Protection

- Optional Hot Dip Galvanizing

- Fabrication Standard

- IS, ASTM, or as specified

- Application

- Base frame for generators, pumps, compressors, machinery, HVAC equipment

- Load Bearing Capacity

- Upto 5 Tons (varies with frame size)

- Mounting Holes

- Provided as per equipment

- Welding Type

- MIG / TIG / Arc Welding

MS BASE FRAME FABRICATION Trade Information

- Minimum Order Quantity

- 5 Pieces

- FOB Port

- india

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 20 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wrapping

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About MS BASE FRAME FABRICATION

We specialize in high-quality MS (Mild Steel) base frame fabrication, designed for durability, strength, and precision. Our fabricated MS base frames are widely used in machinery, industrial equipment, power plants, generators, pumps, compressors, and other heavy-duty applications. With advanced welding, cutting, and finishing techniques, we ensure robust structures that provide excellent load-bearing capacity and stability. Our frames are customized to meet industry-specific requirements, offering corrosion resistance, precise alignment, and long-lasting performance.High-Strength Fabrication for Industrial Demands

MS Base Frames are engineered with high-quality mild steel and advanced welding techniques like MIG, TIG, or Arc, ensuring exceptional strength and longevity. Strict adherence to IS and ASTM standards, along with precise dimensional tolerances up to 1 mm, guarantees stability and performance in demanding industrial environments.

Customizable Design and Efficient Assembly

Each base frame can be tailored to specific size, shape, and load requirements. Delivered fully assembled or knocked down, installation is flexible to suit project schedules. Mounting holes are precisely located to match your equipment, and finished surfaces (powder coated, painted, or galvanized) provide additional protection against wear and corrosion.

Quality Control and Corrosion Protection

A comprehensive QC system includes visual inspections, dimensional checks, and welding quality tests. For enhanced longevity especially in harsh environments, optional hot dip galvanizing is available. These measures ensure that every base frame maintains optimal performance and safety throughout its lifecycle.

FAQs of MS BASE FRAME FABRICATION:

Q: How is the load-bearing capacity of the MS Base Frame determined?

A: The load-bearing capacity depends on the frames size and design, with models supporting up to 5 tons. Specific requirements can be accommodated by customizing the frame dimensions based on customer drawings and intended application.Q: What grades of steel are used in the fabrication of MS Base Frames?

A: MS Base Frames are manufactured using mild steel conforming to IS 2062 or equivalent international standards, ensuring reliable structural integrity and compatibility with industrial usage.Q: When is hot dip galvanizing recommended for corrosion protection?

A: Hot dip galvanizing is advisable when base frames will be deployed in corrosive, outdoor, or humid environments. This optional surface treatment greatly increases the frames resistance to rust and extends its service life.Q: Where can MS Base Frames be used?

A: They are utilized as support structures and mounting bases for industrial equipment such as generators, compressors, pumps, machinery, and HVAC units in factories, plants, and commercial installations across India.Q: What is the process for ordering a custom MS Base Frame?

A: Customers can provide detailed equipment drawings and specifications. The manufacturer will fabricate the base frame with custom dimensions, load ratings, mounting configurations, and preferred surface treatments, ensuring precise fit and performance.Q: How are the frames delivered, and what are the assembly options?

A: MS Base Frames can be shipped fully assembled for immediate installation, or in a knocked-down format for convenient handling and on-site assembly, depending on the clients preference and logistical needs.Q: What are the benefits of using a welded fabricated MS Base Frame?

A: Welded fabrication provides high strength, rugged build quality, and precise dimensions. Combined with customizable features, corrosion resistance, and quality control measures, these frames ensure safe, reliable, and long-term support for industrial equipment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Spare Parts For Transit Mixer Category

MS DUCT FABRICATION SERVICE

Price 200 INR / Ton

Minimum Order Quantity : 1 Ton

Feature : Other, Corrosion Resistance, Durable, Custom Fabrication

Control System : Other, Manual Operation

Color : Silver or as required

Automatic : No

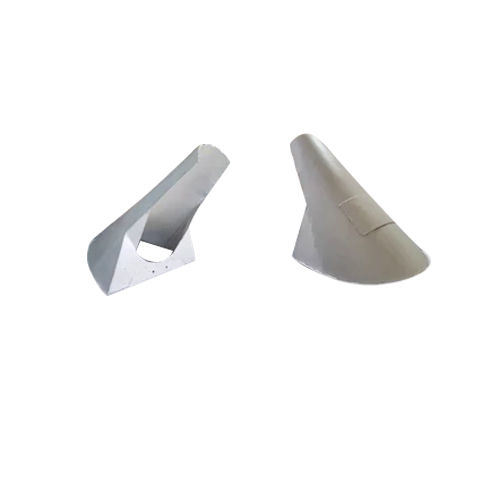

DKV Discharge Chute for the Transit Mixer Machine

Price 18000 INR / Piece

Minimum Order Quantity : 2 Pieces

Feature : Easy to use

Control System : Manual

Color : Gray

Automatic : Yes

DKV V Chute For Transit Mixer Machine

Price 5000 INR / Piece

Minimum Order Quantity : 10 Pieces

Feature : Easy to use

Control System : Manual

Color : White

Automatic : Yes

DKV Charging Chute for Transit Mixer Machine

Price 15000 INR / Piece

Minimum Order Quantity : 2 Pieces

Feature : Easy To Move

Control System : Manual

Color : White

Automatic : Yes